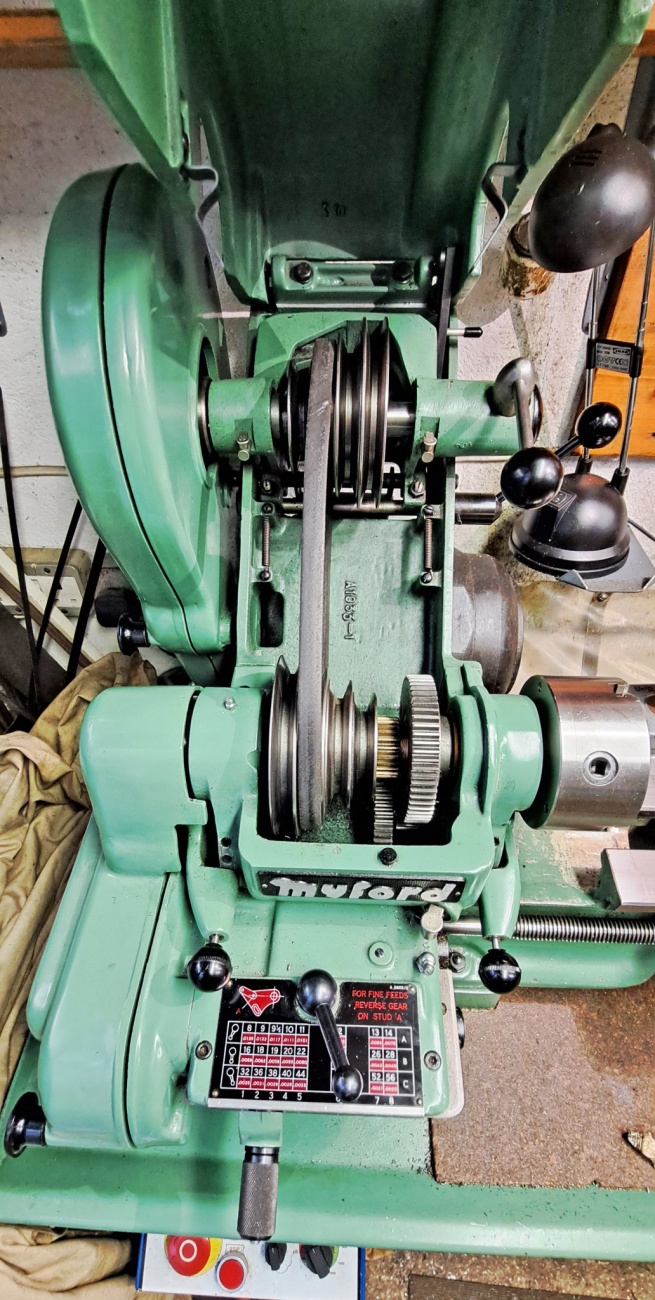

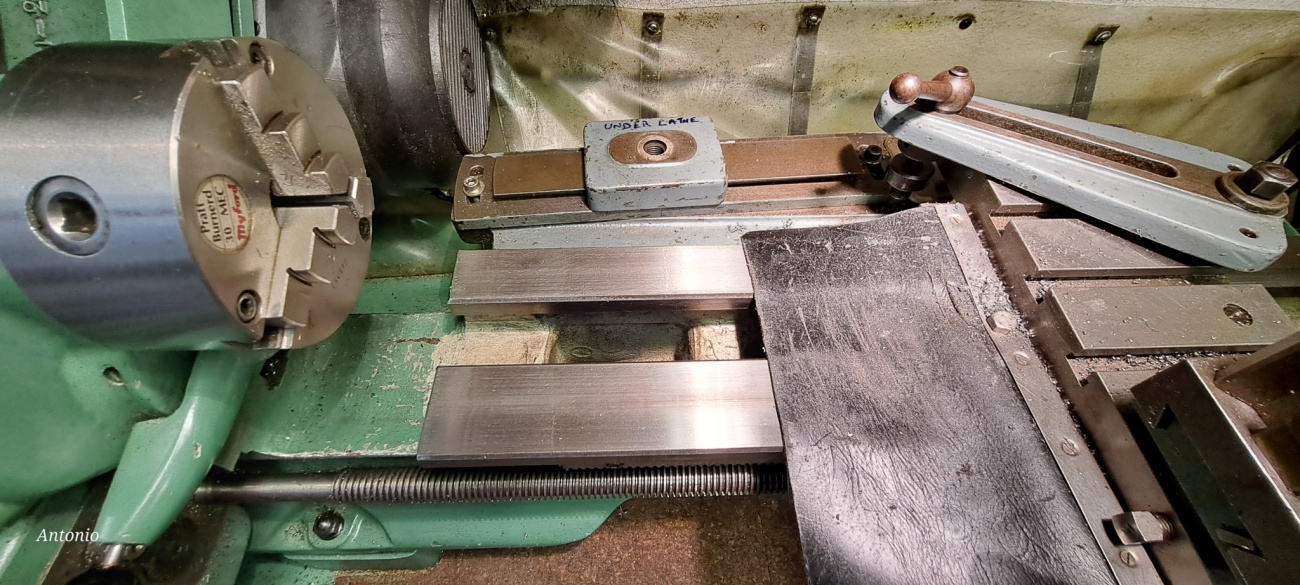

Machine Details

| Manufacturer | Myford |

|---|---|

| Model | Super 7BPXF |

| Location | United Kingdom |

| Asking Price | £4,850.00 |

Contact Details

Contact details are hidden for inactive ads.

Myford Super 7B lathe 3.5” x 19” gap-bed with a screwcutting gearbox, power cross feed, hardened bedways, mounted on the maker’s industrial cabinet stand and driven by an expensive Newton-Tesla infinitely-variable speed drive. One owner from new, in pristine condition and very well equipped with: taper-turning unit, Myford diving head with 12 division plates, a boxed set of spindle-nose 2 Morse taper collets, metric screwcutting conversion set, a late-model milling slide with 2 bolts per axis and the correct machine vice, Dickson-type quick-set toolpost with 19 tool holders, two rear tool posts, fixed steady, travelling steady, hand-turning rest with 2 Ts, a second hand-turning rest adapted to a twin-roller filing jig, a very useful Keats angle plate for faceplate mounting, verdict test indicator, two other dial indicators, 4-jaw independent chucks - 6-inch, two 5-inch and a 3-inches in diameter. 3-jaw chuck, 2 tailstock capstan units, 4 tailstock chucks of various sizes, tailstock rotating centre, angle plates, boring bars, drive dogs, tailstock V-pad, faceplate, micrometers, tailstock sliding die holder, small and large faceplates, catchplate, Morse centres, wood-drive centre, adjustable tailstock off-set centre, a bar with headstock spindle, turning and boring tools and many smaller parts. This was the owner's smallest lathe and used only for clock and watchmaking.