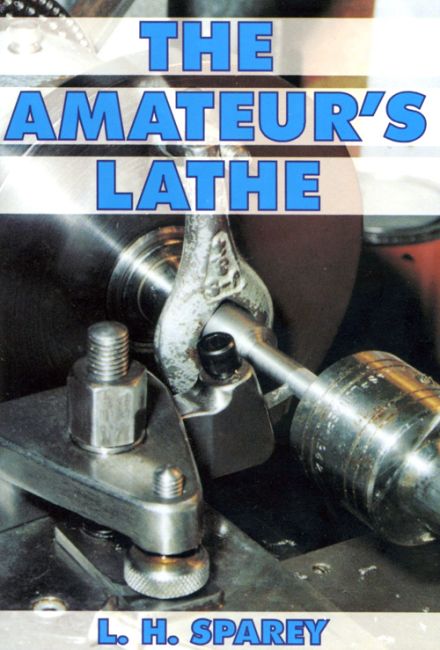

The Compact Lathe

The Compact Lathe. A book that explains how to get the best from a Unimat 3, Toyo, Cowells, Flexispeed, Peatol or similar small lathe. Second Revised Edition. The author brings his experience to bear in helping the beginner make the most of these lathes' surprising versatility. Clear illustrations and a host of technical data help owners progress to more ambitious tasks.