For Sale: SIP MU-4R Jig Borer/Milling Machine

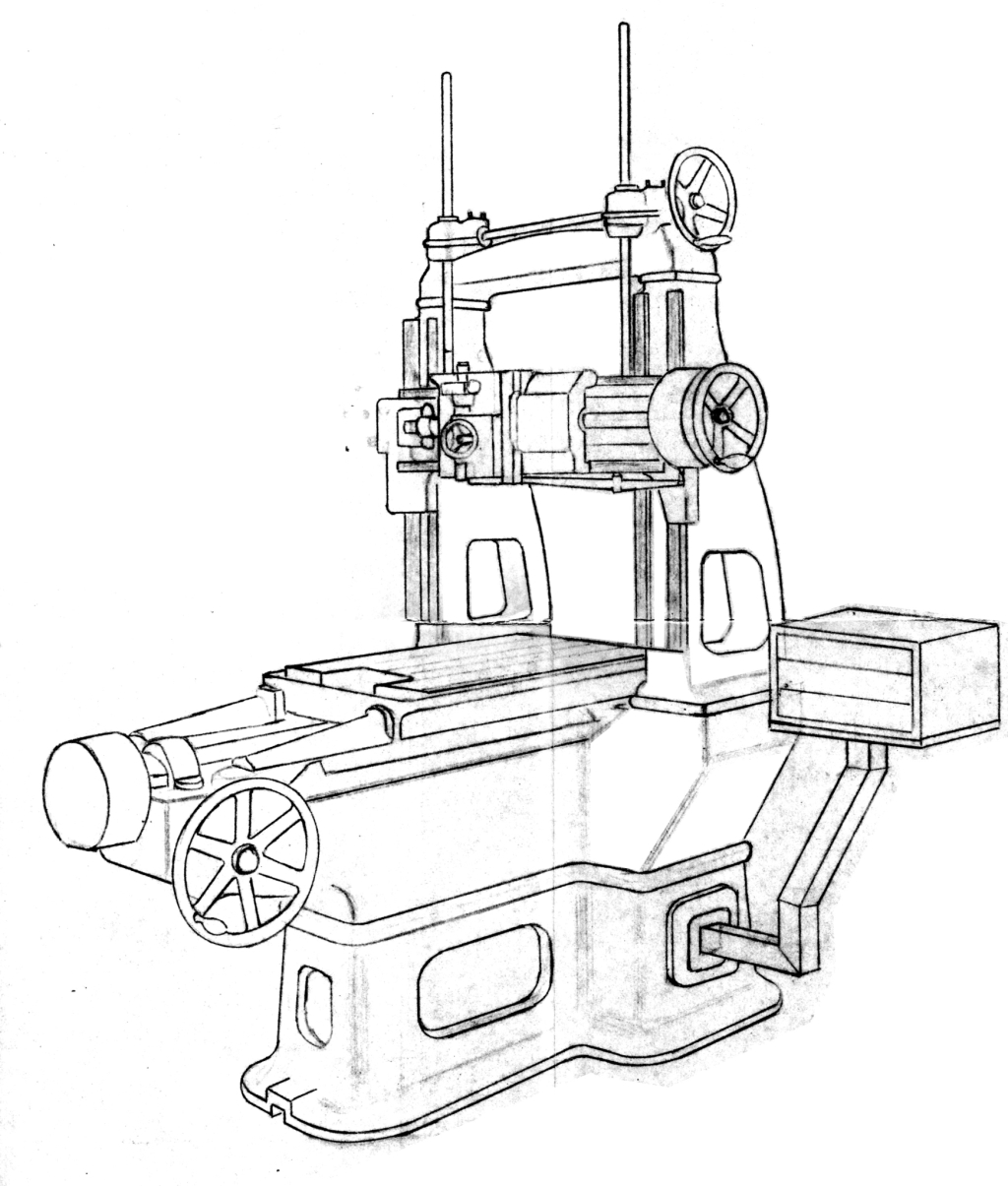

SIP SP-4 Jig borer / milling machine. When bought, this fine jig borer had been converted to a coordinate measuring machine but is now back to its original function using a Warco ZX-15 3 Morse spindle. No modifications were necessary to the borer save for the removal of the measuring probes holder (which is supplied) and using the original bolt holes to carry the head on the cross beam saddle. The 19" x 27" T-slotted table is unblemished, and a longitudinal travel of around 25“. The cross beam carries a saddle on which the milling head is mounted; the head covers almost the full table width and is operated by a handwheel to give a travel of approximately 16-18”. The distance between table and spindle nose is approximately 25“. The table is traversed longitudinally by a large handwheel driving the leadscrew very smoothly through closely meshed gearing with barely detectable backlash. The table and saddle movements are covered by a DRO reading to 0.0001” and metric equivalent. There is no DRO on the down feed of the cross beam which is also controlled by a handwheel, operating through closely matched bevel gears and two feedscrews so it keeps its alignment parallel to the table. The upper ends of the feedscrews are normally protected by a tubular steel sleeve (currently removed due to headroom). Fine control of the down feed is on the milling head which has the options of screw feed for milling or lever feed for drilling. No doubt a digital readout device could be adapted to fit. The milling head can be angled 90 degrees on either side of vertical but the crude rivetted-on scale has been removed and is set by a digital clinometer with a magnetic base (not supplied but readily available). This can be set to zero on the table and then attached to the spindle when extended downwards, or other datum surface, and records the angular movement.

The milling head has its standard 3-phase motor and the inverter to drive it is supplied complete with a remote control box attached to the machine

While it's a superb machine and I was in the process of devising a motorised feed to the rather slow cross beam down feed - but time marches on and a house move looms. The buyer is welcome to the motor with reduction gearbox and the mounting platform made so far – it needs only a little work to finish. Also supplied is a large machine vice with 5” wide jaws and opening to 5” in 2 stages; various spindle tooling including 3 x shell end mills and arbors; Clarkson small autolock with 4 metric and 4 imperial collets and spanner; boring head; arbor for gear cutters; Jacobs chuck with key; various drawbars. The handbook is for the measuring machine but may be of some use.

This is a large machine with a static footprint of 64” x 48” and a max height with cross beam in highest position of about 7’ 6” due to the long feedsrews. I had to remove the cross-beam supports to get it through my garage door. It is also heavy – estimated at just over 1 tonne – so someone with a truck fitted with a 1-tonne Hiab would need to make 2 journeys. Getting a large flatbed into my yard is impossible, however, I can dismantle the machine and know someone able to transport it for re-erection – but prospective buyers would need to negotiate with him. £2900 or close offer considered. peter@smithurst.org. Details of SIP jig borers here