Myford MG12 Grinder Operation & Parts Manual & Catalogue

Myford MG12 Cylindrical Grinder: Detailed Instruction Manual with the Illustrated Parts Manual as clear Sectional Drawings, an Electrical Schematic and a copy of the maker's Sales & Technical Specification Catalogue.

Myford MG12 HA and MG12 HAC Grinder Manual

Myford MG12-HA/HAC Grinder: Instruction Manual and a Parts Manual as Detailed Sectional Drawings an Electrical Schematic and copy of the Maker's Sales, Technical Specification & Accessories Catalogue.

Myford MG12 HPT Grinder Manual

Myford MG12-HPT Grinding Machine with Automatic-cycle Traverse and Plunge Grinding: Large and detailed Instruction Manual, Parts as Detailed Sectional Drawings and Individual Electrical Schematics for the MG12H and MG12-HPT.

Myford MG12-HA, MG12-HA-HAC and MG12-HP-HPC Grinder Manual

Myford MG12-HA (standard settling tank), MG12-HAC (coolant filtration system) and MG12-HP-HPC with Automatic-cycle Traverse and Plunge Grinding: Instruction Manual, Parts as Detailed Sectional Drawings, Electrical Schematics and the the supplement covering the Plunge Feed mechanism.

Myford ML10 "Book of the Myford ML10"

Myford "ML10 Lathe Manual" (Book of the ML10). Detailed user's guide and operating instructions.

Myford ML7 lathe First-ever 1947 Manual and Catalogue Set

Myford ML7 Instruction and Maintenance Manual. Reproduction of the original 1946 version with the first-ever price list. Interesting, but scanty data.

Myford ML7R Manual and Accessories

Myford ML7R Instruction and Maintenance Manual with Parts as Exploded Component Drawings together with a Sales and Specification catalogue showing the complete accessory range. Increased in size from A5 to A4 for easier reading and clearer drawings and diagrams.

Myford Mini-Kop Mk.1 Manual

Myford Mini-Kop Mk.1 - the very first type based closely on the ordinary Super 7 lathe, even to the use of a screwcutting gearbox. detailed Operation, Maintenance and Parts Manual. Read all about Min-Kop lathes here http://www.lathes.co.uk/myfordminikop/

Myford Mystro Wood-turning Lathe Operation, Maintenance and Parts Manual

Myford Mystro Wood-turning Lathe Operation, Maintenance and Parts Manual and every variation of the wiring diagrams. Includes a copy of the Mystro Sales, Technical Specification and Accessories catalogue and price lists.

Myford Planer and Thicknesser Collection

Myford Planer and Thicknesser. A compendium of data from all publications about the machine - both the lathe-mounted version and the mechanically identical bench machine. Illustrated advertising & technical sheets; Exploded parts diagram and list; Installation, Maintenance and Operation Instructions; Instructions for sharpening and setting the planer blades.

- Operators Manual

- Maintenance Manual

- Parts Manual

- Catalog

Myford Screwcutting Gearboxes - data pack

Myford Screwcutting Gearboxes. There were two versions of the box: the earlier had a train of external gears under a detachable cover on its right-hand face, the later version was entirely enclosed.

Rishton VM602 and VM452 Milling Machine Manual

Rishton VM602 and VM452 Vertical Milling Machines. Detailed Operator's Instruction, Maintenance Manual and Parts Manual as Exploded Component Drawings - with an electrical schematic. Includes a complete set of Rishton Sales & Accessories catalogues.

Rodney Milling Attachments Instruction Sheet & Catalogue

Rodney (Myford Rodney) Milling Attachments: Full-size and Mini.

- Operators Manual

- Catalog

SPAREY SCREWCUTTING GEARBOX Myford ML7 - two large technical drawings

SPAREY SCREWCUTTING GEARBOX (this was an early box designed for the ML7

and intended for home construction) - two large technical drawings showing how

to machine and assemble the box.

The ML7 W.M.E.D "Easy Change Screwcutting Attachment" Manual

The ML7 W.M.E.D "Easy Change Screwcutting Attachment". Notes on Installation and Operation.

Pagination

Parts & Accessories

Find other items for sale on our Parts & Accessories page.

Pagination

- Previous page

- Page 2

Related Books

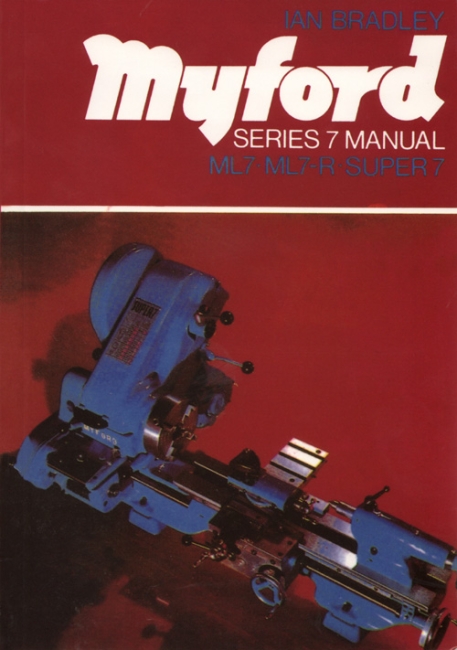

Myford Series 7 Book

The long-awaited reprint of the definitive Myford book covering the ML7, ML7-R and Super 7 lathes. Includes detailed operating and maintenance instructions, details of construction, how to install, use of appropriate lathe tool, use of accessories, details of home-made additions and threading table, etc.