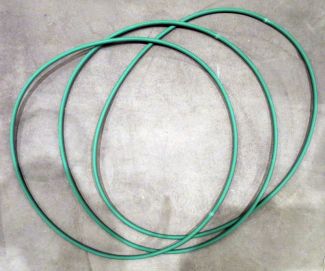

Emcomat 7, 7L, 8.4, 8.6, V8 lathes belt -WIDE 1-inch

Emcomat 7, 7L, 8.4, 8.6 and V8 lathes: drive belt, toothed type 1-inch (25mm) wide. Unfortunately, this belt is now out of production - but the 3/4" (20mm) belt for the earlier version of this lathe fits and works just as well - but clearly, if the lathe is hard used, will not last as long.