Narrow V-Belt for a range of Chinese-made lathes: Axminster, Warco, Chester, etc: 5 x 710 mm

Sold by various importers including Axminster, Chester, Warco, etc. The "920", "CT-918" lathe and other Model Numbers - a Chinese-made lathe that was, in effect, a developed copy of the Emco Compact 8.. This is a narrow, 5 mm wide V-belt - and is normally tensioned by a lever on the headstock. This belt is a top-quality, USA-made product.

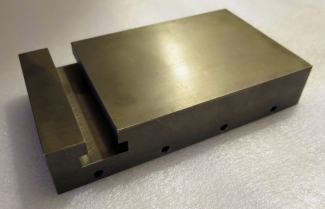

Boxford Lathe Tumble Reverse Gear - Early Models 14.5-degree pressure angle

Boxford lathe Tumble Reverse Gears 14.5 pressure angle - Early Models

This gear is for all Models prior to Serial Serial No. 11-13513 - the introduction of the Mk.2 Models that have a single lever on top of the headstock to engage the backgears. 32 teeth and a 14.5-degree pressure angle. Made in the correct grade of cast iron - we have sold these gears for over 30 years.

For later models (the Mk. 2 AUD, BUD and CUD) with a 20-degree pressure angle see here.

Myford Super 7 and ML7R Drive Belts Z-section T-Link

Motor to countershaft and countershaft to headstock belts of the NuT-Link Type in a Z-Section. Link belts help to reduce the vibration normally passed from a single-phase motor to the lathe - and was a fitting often used by Myford Service engineers to "quieten" a noisy machine. On the Super 7 and ML7R, the T-link belt is highly effective on the drive from motor to countershaft.

Myford Super 7 and ML7R Drive Belts - PowerTwist

PLEASE READ ALL OF THE FOLLOWING CAREFULLY: The only PowerTwist belt needed on the Super 7 and ML7R is an "A" section from the countershaft to the headstock. The use of this belt guarantees that the lowest speed will be available as, when fitted with the metal-pin NuT-link there may not be enough room between the inner face of the headstock and the largest pulley on the main spindle.

Emco Compact 10 Drive belts

Special narrow (7mm across the top) drive belts for the Emco Compact 10 lathe. Sold as a pair (Code GtM7)

Tyme Avon Wood Lathe Drive Belt

The special high-quality, UK or EU-made belt for the headstock drive on the Tyme Avon Wood Lathe.

There is also a manual available for this lathe

A belt for the Tyme CUB lathe can also be provided

Tyme Cub Wood Lathe Drive Belt

Tyme Cub wood-turning lathe A UK or EU-made high-quality headstock spindle drive belt.

A manual can also be provided for this lathe

A belt can also be provided for the Tyme AVON lathe

Hobbymat Lathe Motor Conversion

The usual problem with Hobbymat motors is a failure of the centrifugal switch or capacitor. We sell the correct capacitor and a set of detailed dismantling instructions for £21 + post (+ VAT in the UK and EU) that allows the motor to be converted to a much better "cap-start-cap-run" configuration - full instructions provided. The conversion allows the motor to start without the need for the troublesome centrifugal switch.

Viceroy Lathes Drive Belts: 1.4m

Final-drive belt for the Viceroy Under-drive lathes such as the TDS Series (TDS-5, TDS5-GB, TDS 1/1-GB, TDS 1/1, Educator, etc. as seen here http://www.lathes.co.uk/viceroy ) The best belt is the Nu-T-link, in an A Section, 1.4 metres (1400 mm) long. Price includes UK post and packing.

Myford ML8 Drive Belt

For the Myford ML8 lathe the new, improved metal-pin T-link belting is ideal. It's a sectional belt so no dismantling is needed to fit it. For lathes on the maker's stand 1.2 metres is the length needed. If mounted on a home-made bench with a thick wooden top, 1.3 metres is usually sufficient. The width required is 1/2" (13 mm) = an "A" section.

Minilor TR1 Lathe Drive Belts

Minilor TR1 lathe and milling head toothed and V drive belts. A complete set of four comprising: toothed 420, 340 and 280 with the V-belt has replaced by a Swiss-made round belt in a high-grip Polycord. Although these belts are all the correct length and tooth pitch, they can vary slightly in width.

Changewheels for Boxford and South Bend "9-inch" lathes

Changewheels for Boxford, South Bend "9-inch" lathes. A full range is available - but we have currently to rebuild this section of the website.

As the list is incomplete, please email tony@lathes.co.uk to order or phone 01298-871633 From overseas: +44-1298-871633 From The USA and Canada: 011-44-1298-8716308:00 to 23:00 Monday to Saturday

Emco Compact 5 Lathe Drive Belts

Emco Compact 5 Lathe Drive Belts. The correct high-quality German-made units. Sold as a pair, large and small.

The drive belt for the Emco Compact 5 and Compact 8 vertical can be found here: https://store.lathes.co.uk/product/19811

Emco Compact 5 and Emco Compact 8 Milling Head Drive Belt

Emco Compact 5 and Emco Compact 8 Milling Head Drive Belt. The is a special, very short belt to fit the vertical milling head fitted to the Emco Compact 5 and Emco Compact 8 lathes and also the stand-alone Emco 5 vertical milling machine.

Drive belts for the Emco Compact 5 lathe can be found here: https://store.lathes.co.uk/parts/drive-belts/emco-compact-5-lathe-drive-belts

Record and Coronet No. 0, 1, 2, 3, CL1, CL2 and CL3 wood lathes. The correct high-quality rive belt.

Record and Coronet No. 0, 1, 2, 3, CL1, CL2 and CL3 wood lathes. The correct, high-quality drive belt. Made in the UK or EU - not China.

Boxford & South Bend Backgear Shaft

Boxford & South Bend Backgear 24-tooth Shaft. We can supply - on a service-exchange basis - a backgear shaft fitted with a new steel gear. The large gear can be knocked off to save postage (though some early shafts were one piece). Early gears have a 14.5-degree pressure angle and have no markings to show this. Later gears are 21 degrees and in this case the shaft is stamped "21" - though it's sometimes hard to see. We can supply both types.

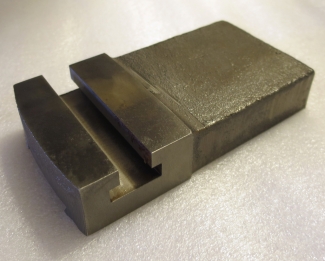

Boxford Tumble-reverse Gears - Late Models 20-degree pressure angle

Boxford Lathe Tumble Reverse Gear - Late Models

This gear is for all Models after Serial Serial No. 11-13513 - the introduction of the Mk.2 Models that have a single lever on top of the headstock to engage the backgears. 32 teeth and a 20-degree pressure angle. Made in the correct grade of cast iron - we have sold these gears for over 30 years.

For earlier Boxford lathes with 14.5-degree changewheels, see here

Hobbymat MD65, Prazimat MD300, Saupe & Sohn, Hobby 120 Sliven and Proxxon version of the Hobbymat Lathe Rotating Tailstock Centre (Live Centre)

Rotating tailstock centre (also called a "live centre") with the correct fitting for the Hobbymat MD65, Prazimat MD300, Saupe & Sohn, Hobby 120 Sliven and Proxxon version of the lathe. This is a special, compact centre with a No.1 Morse taper arbor that gives the best possible tool clearance on small jobs,

Boxford and South Bend Lathes: Metric to inch conversion gear 127/135T

Boxford and South Bend Lathes: Metric-to-inch screwcutting transposing correctly gear 127/135T. Properly made in cast iron in the UK.

For the Inch to metric transposing gear pair, see: https://store.lathes.co.uk/product/11900

Coronet & Record "MAJOR" Lathes Late-Models - drive belt

The correct, high-quality, UK or EU-manufactured flat-backed belt with 5 multi-V grooves on the inside to fit late-model Coronet and Record "Major" wood turning lathes and the multi-function machines based on this machine.

The earlier Major used an ordinary V-drive belt and this can be ordered here: https://store.lathes.co.uk/product/20057

Emco Compact 8 Toothed Drive Belt

The wide, toothed belt for the Emco Compact 8 and the similar copies made in Taiwan.

The narrow V-belt can be found here: https://store.lathes.co.uk/parts/emco-compact-8-narrow-v-belt

Boxford 2-pin gear to fit on headstock spindle and engage with the pulley

38-tooth gear to fit on the headstock spindle and engage with the headstock pulley as part of the backgear system.

The gear was made with two pressure angles:

1) 14.5-degrees for older lathes with a swing-type quadrant lever on the front face of the headstock, like this http://www.lathes.co.uk/boxford/img10.jpg

Emcomat 7, 7L, 8.4, 8.6, V8 lathes belt -WIDE 1-inch

Emcomat 7, 7L, 8.4, 8.6 and V8 lathes: drive belt, toothed type 1-inch (25mm) wide. Unfortunately, this belt is now out of production - but the 3/4" (20mm) belt for the earlier version of this lathe fits and works just as well - but clearly, if the lathe is hard used, will not last as long.

Thread Dial Indicators for Boxford, South Bend and Smart & Brown Lathes

Thread Dial Indicators to fit Boxford, South Bend "9-inch" lathes and Smart & Brown Sabel, SAB and S lathes - with Imperial 8 t.p.i. pitch leadscrews and for other makes of lathes (such as the Harrison M300 and some Colchester Bantam lathes) with 6 mm pitch leadscrews. Use the 'down-arrow' box below to select the one you need.

Raglan 5-inch Lathe Top-slide

Raglan "5-inch" Lathe - the upper top slide casting (a picture of this model here). It is not uncommon for this slide to snap in two across the front edge of the T-slot.

Raglan Little John Top Slide

The upper top slide casting for the Raglan Little John lathe. It is not uncommon for this slide to snap in two across the front edge of the T-slot. Machined complete ready to fit - though you have to transfer the gib-strip adjustment screws and, once assembled, drill and tap the holes to secure the feed-screw end plate.