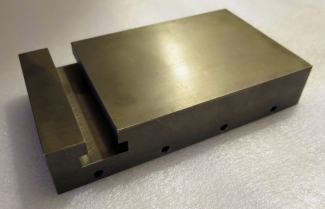

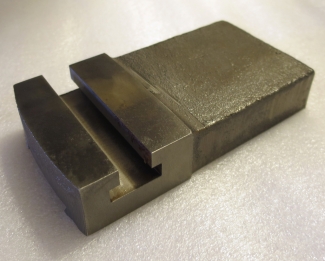

Boxford and South Bend 100/127t inch to metric conversion gear

Boxford, South Bend & Smart & Brown 100/127t inch-to-metric screwcutting transposing gear. This gear set will convert all imperial (inch) belt-drive Boxford lathes (except the late VSL Type), the South Bend 9-inch and the Smart & Brown Sabel, SAB and S lathes to cut metric pitches. Presently, this gear is only available as two separate gears that need pinning, together - a simple process.