All types of drive belts supplied: V, flat, round (leather & plastic), linked belts, variable-speed, poly-V, etc.

We sell drive belts custom-made to your specification, as well as prefabricated belts for specific machines or applications.

For immediate delivery or straightforward advice about any belt feel free to call us. No order is too small.

We also stock miniature V-belts (6 & 8mm top widths) and the special belts for: Axminster 918, Warco 918 (and similar developed copies of the Emco Compact 8), Naerok and Seeley bandsaws, etc.

Belts also stocked or made for a variety of popular Lathes & Millers: Myford, Boxford, Emco, Unimat, Axminster, Warco, Colchester, Harrison etc.

Advice on how to ensure that you order the correct length of flat belting can be found here.

Custom Drive Belts

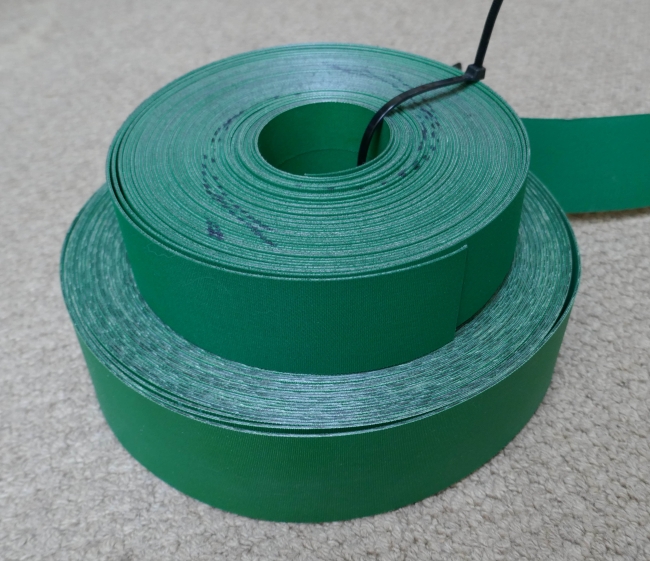

The ideal installation for any machine tool is an endless Betalon-Multiply belt: these are light in weight but immensely strong and stretch resistant. They absorb shock loads well, have a high coefficient of friction, enjoy a proven record of reliable industrial service and can be made in almost any combination of length and width.

This belt (unlike cheaper alternatives cut from conveyor belts and cheap copies made in India) is UK-made, enormously strong, densely woven and specially designed for machine-tool use.

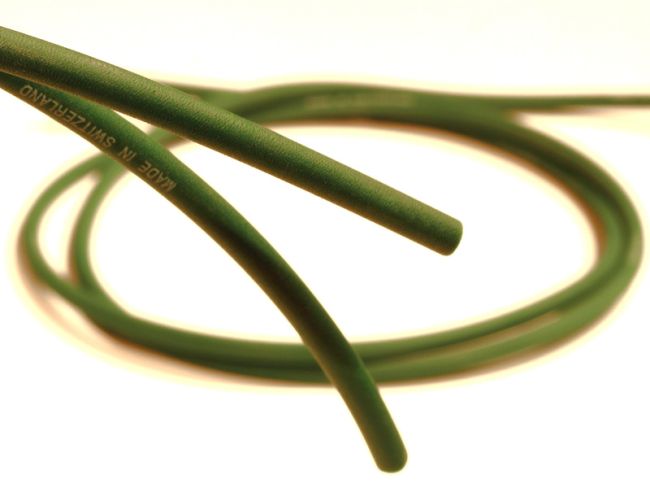

Polycord Belting - immediate delivery from stock. This makes an excellent, long-life application for hard-worked machines - from models though engravers to small lathes and millers, etc. Our solid plastic belting is made in Switzerland and of the very best quality. We can produce belts of practically any length down to 140 mm long using a jigged joint and heat weld. Although all belts stretch, Polycord is more resistant than most, especially when 6mm in diameter or over.

This makes an excellent, long-life application for hard-working machines. Our plastic belting is of the very best quality and is made in Switzerland. Hollow belts are easy to fit without dismantling the machine or having to melt the ends of the belt together. However, if you need a belt with minimum stretch, the solid type, available here, is the better choice.

Early lathes, light-duty milling machines, drills, Singer and other makes of sewing machine and assorted power tools were often driven by a round leather belt, sometimes referred to in contemporary literature as a "gut" drive. This type of belting is also used in furniture and similar products. It is still available and usually in stock for immediate delivery. The belt colour is actually a light tan - and far lighter than shown in the photograph. Please note: the stated diameter of the material is nominal i.e. the measurement might be a little under or over the given figure.

A new development of an old idea - a link belt without metal fasteners. This is highly effective on all lighter machine tools and especially useful on precision lathes and millers where a "softer" drive, free from vibration, is appropriate.

This is the superior replacement for the original "Brammer" black-fabric "round-end" link-belting that was held together with mushroom-headed metal pins each (usually) stamped with a letter "B". The new belts have only a slight curve to the end of each link and the head of the pins are now "T" section.

Drive belts for the Colchester Chipmaster and the HARRISON Lathe AA Mk. 1 (a lathe identical to the Chipmaster). No belt details are given in the boxes below becasue the belts fitted to these lathes varied over the years. Hence, it's best to phone 01298-871633 to discuss what you need.

From overseas: +44-1298-871633 and from the USA and Canada dial 011-1298-871633

The correct drive belt for the Luna SP800, SP1000 & Woodman SP800 wood-turning lathes. Other sellers will have also branded these lathes under various names. The belts are 22 inches (559mm) long, 0.8 inches wide (10 mm) and have 4 small V-grooves on the drive surface. Fill in the belt width and length details below; the order will then work automatically.

Drive Belts in Stock

We offer a number of endless belts for common machine tools, and can also supply numerous other belts not listed here. Contact us to place an order.

Sold by various importers including Axminster, Chester, Warco, etc. The "920", "CT-918" lathe and other Model Numbers - a Chinese-made lathe that was, in effect, a developed copy of the Emco Compact 8.. This is a narrow, 5 mm wide V-belt - and is normally tensioned by a lever on the headstock. This belt is a top-quality, USA-made product.

Motor to countershaft and countershaft to headstock belts of the NuT-Link Type in a Z-Section. Link belts help to reduce the vibration normally passed from a single-phase motor to the lathe - and was a fitting often used by Myford Service engineers to "quieten" a noisy machine. On the Super 7 and ML7R, the T-link belt is highly effective on the drive from motor to countershaft.

PLEASE READ ALL OF THE FOLLOWING CAREFULLY: The only PowerTwist belt needed on the Super 7 and ML7R is an "A" section from the countershaft to the headstock. The use of this belt guarantees that the lowest speed will be available as, when fitted with the metal-pin NuT-link there may not be enough room between the inner face of the headstock and the largest pulley on the main spindle.

Final-drive belt for the Viceroy Under-drive lathes such as the TDS Series (TDS-5, TDS5-GB, TDS 1/1-GB, TDS 1/1, Educator, etc. as seen here http://www.lathes.co.uk/viceroy ) The best belt is the Nu-T-link, in an A Section, 1.4 metres (1400 mm) long. Price includes UK post and packing.

For the Myford ML8 lathe the new, improved metal-pin T-link belting is ideal. It's a sectional belt so no dismantling is needed to fit it. For lathes on the maker's stand 1.2 metres is the length needed. If mounted on a home-made bench with a thick wooden top, 1.3 metres is usually sufficient. The width required is 1/2" (13 mm) = an "A" section.

Minilor TR1 lathe and milling head toothed and V drive belts. A complete set of four comprising: toothed 420, 340 and 280 with the V-belt has replaced by a Swiss-made round belt in a high-grip Polycord. Although these belts are all the correct length and tooth pitch, they can vary slightly in width.

The correct high-quality drive belts for Myford Mystro wood-turning lathes.

There are two belts:

10 mm wide for the standard machine and about 20 mm wide for the variable-speed model. Click the down arrow in the box below to select the one you need.

Emco Compact 5 Lathe Drive Belts. The correct high-quality German-made units. Sold as a pair, large and small.

The drive belt for the Emco Compact 5 and Compact 8 vertical can be found here: https://store.lathes.co.uk/product/19811

Record and Coronet No. 0, 1, 2, 3, CL1, CL2 and CL3 wood lathes. The correct, high-quality drive belt. Made in the UK or EU - not China.

The correct, high-quality, UK or EU-manufactured flat-backed belt with 5 multi-V grooves on the inside to fit late-model Coronet and Record "Major" wood turning lathes and the multi-function machines based on this machine.

The earlier Major used an ordinary V-drive belt and this can be ordered here: https://store.lathes.co.uk/product/20057

Emcomat 7, 7L, 8.4, 8.6 and V8 lathes: drive belt, toothed type 1-inch (25mm) wide. Unfortunately, this belt is now out of production - but the 3/4" (20mm) belt for the earlier version of this lathe fits and works just as well - but clearly, if the lathe is hard used, will not last as long.

Drive belt for late-models Coronet Elf, Minor, Minorette wood lathes. High-quality UK or EU-manufactured

After some difficulty obtaining reliable and correctly-made supplies of Emco Unimat belts we have decided to offer instead the special Swiss-made drive belt we sell for light industrial applications. It's widely used on all sorts of drives and we now sell lots for watch and clockmaker's lathes - and of course various kinds of Unimat. It's long-lasting and very reliable.

Unfortunately, these belts are now very difficult to obtain with minimum orders and expensive with post from the EU. As an alternative, I suggest using a 1.1 metre length of 7 mm Polycord round belting. It's a special Swiss-made machine-tool drive type and very effective and can be joined into the lengths needed for a Toyo ML360. It can be ordered here with full joining instructions provided..

http://store.lathes.co.uk/belts/solid-round-plastic-belting

The correct drive belt for the Hobbymat Wood lathe MD120 and MD150 - also branded as the Prazimat Al-Co Kober, HMD 8502 and Farmer.8/425

The correct variable-speed drive belt for the Little John Mk.1 and Mk.2 Models. These belts are high-quality, industrial-grade belts made in Europe. An installation tip: The manual suggests swivelling the layshaft housing about bolt 'D'. However, a better solution is to remove the grub screw (at the rear) securing the shaft to the housing; the housing can then be slid off the layshaft allowing it to move further, thus giving enough clearance to remove & refit the belt.

The correct variable-speed drive belt for the Raglan "5-inch Lathe" These belts are high-quality, industrial-grade belts made in Europe. installation tip: The manual suggests swivelling the layshaft housing about bolt 'D'. However, a better solution is to remove the grub screw (at the rear) securing the shaft to the housing; the housing can then be slid off the layshaft allowing it to move further, thus giving enough clearance to remove & refit the belt.

Raglan Milling Machine. The correct variable-speed drive belt

The belt for the Little John Lathe can be found here

The belt for the Raglan "5-inch" lathe can be found here

After some difficulty obtaining reliable and correctly-made supplies of belts for Emco Unimat SL1000 (DB200 in the USA) we have decided to offer instead the special Swiss-made drive belt we sell for light industrial applications. It's widely used on all sorts of drives and we now sell lots for watch and clockmaker's lathes - and of course various kinds of Unimat. It's long-lasting and very reliable.

Boxford VSL Boxford Lathe Vari-speed belt. Unfortunately, the exact belt is no longer available but one close can be supplied. In order to obtain the whole speed range, this will need 1/4" (6mm) packing piece between cross-shaft and hangers to increase the distance to the motor. However, this is not essential as only a little of the slowest speed will be lost if the belt is fitted "as-is". Sent insured by Royal Mail Special Delivery.

A pair of Hobbymat - Prazimat Lathe belts. Top quality, made in Germany. For smooth, vibration-free running at high speedsof it is recommended that both belts be changed at the same time. One each of the two sizes: short and long.

A belt for the Hobbymat - Prazimat Wood Lathe Models MD120 and MD150 click here to order

Final drive belt for Boxford Underdrive lathes. For this application, 1.4 metres of A-section Nu-T-link is needed.