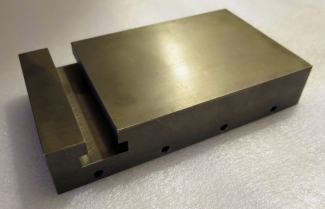

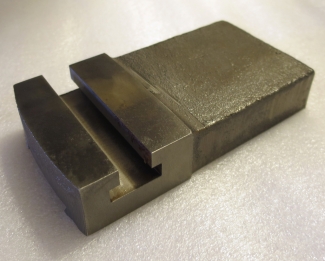

Boxford and South Bend Lathes: Metric to inch conversion gear 127/135T

Boxford and South Bend Lathes: Metric-to-inch screwcutting transposing correctly gear 127/135T. Properly made in cast iron in the UK.

For the Inch to metric transposing gear pair, see: https://store.lathes.co.uk/product/11900